What is Induction Heating?

Heat treating is a controlled heating and cooling process that alters the physical properties of the metal to achieve a specific requirement. In most cases, it is used to increase strength, hardness and wear resistance of metal components.

While there are many methods of heat treatments such as nitriding, caburizing, flame hardening, laser hardening and others, DKK specialises in Induction Hardening which uses electromagnetic induction to generate heat efficiently. A coil connected to a power source creates a magnetic field, inducing an electric current (eddy current) in a metal workpiece, which heats up due to resistance (Joule heat).

By shaping the coil to match the desired treatment area, heat is applied precisely where needed. Higher frequencies concentrate the current on the surface (skin effect), allowing control over hardness depth based on part size and treatment requirements.

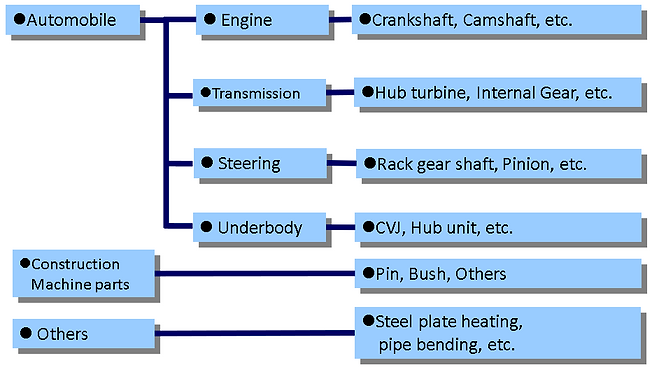

Heat treatments are for...

Induction Heating Machines play a crucial role in various industries, particularly in automotive manufacturing, where they are used for heat-treating components such as crankshafts, gears, drive shafts, axles, engine valves, camshafts, and bearings to enhance their strength, precision, and longevity.

Other ares include construction and heavy equipment manufacturing where components such as excavator and bulldozer parts, hydraulic cylinder rods, and gears for heavy machinery benefit from induction hardening.

Maintenance and Repair Services

In high-frequency heat treatment equipment, maintenance and repair support are critical to ensure reliable operation. The machines contain a large amount of moving parts, and the components undergoing heat treatment are vital to performance, meaning failures are not an option. This makes regular maintenance essential to prevent unexpected downtime and maintain operational efficiency.

Since establishing our Indiana-based facility in 2004, DAI has been committed to providing top-tier maintenance and support services. We continuously strive to ensure that our customers can operate with confidence, knowing their equipment is in optimal condition. Through proactive maintenance and expert repair services, we help maximize uptime, extend equipment lifespan, and maintain the highest standards of quality and performance.

Supply Records

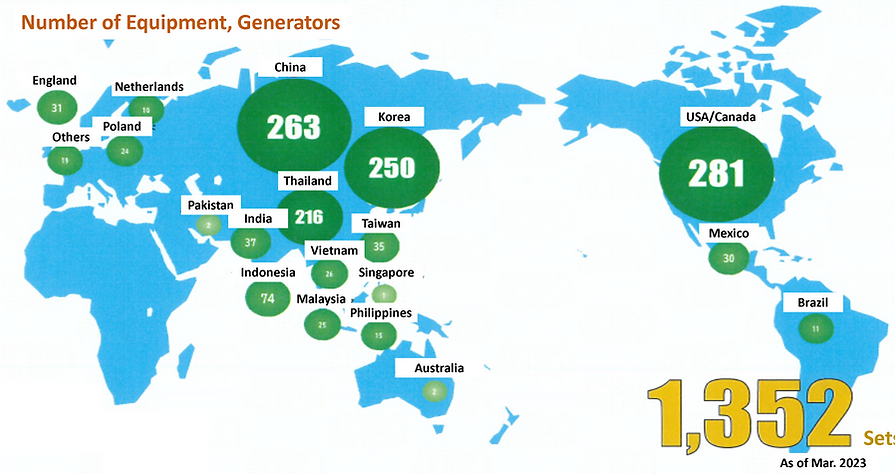

-

Over 2,100 equipment installed worldwide

-

Contracted heat treatment processing at multiple locations

-

107 registered industrial property rights, including 87 patents

-

High-frequency generators for the generation of plasmas in semiconductor manufacturing

-

High-frequency power generators for nuclear fusion plasma heating

-

Designing, manufacturing of power supplies for high-frequency accelerators

Induction Heating Equipment / Maintenance & Repair Service

For Automobile, Construction, Industrial

-

Induction Hardening & Tempering of Crankshaft

-

Quenching & Tempering of Camshaft, Motor Rotor

-

Hardening & Tempering of CVJ, Hub Unit, Rack Shaft

-

Quenching & Tempering of Axle Tube

-

Quenching of Crawler, Sprocket, Ball Screw, Large Ring

-

Billet Heaters, Steel Plates & Melting etc.

TRSC・CTG Series

PTG Series

TRP Series

VFG Series

Coil Design and Production

Heating Coils made by 3D Printer

Size adjustable heating coils

Heat treatment simulation